STÜKEN MEANS MORE

With our precision parts, we implement solutions that even experts would not have considered feasible. We combine complex technologies, finishing processes and services and achieve results that add value for our customers.

Menu

STÜKEN MEANS MORE

With our precision parts, we implement solutions that even experts would not have considered feasible. We combine complex technologies, finishing processes and services and achieve results that add value for our customers.

Contact

Hubert Stüken GmbH & Co. KG

Alte Todenmanner Str. 42

31737 Rinteln

Germany

Phone +49 5751 702 0

info@stueken.de

Further Contacts

Here you will find our international production and sales locations.

STÜKEN MEANS MORE Demand Orientation

As a specialist for stamped and formed parts, we are your partner for high-quality, inexpensive and durable products. In this way we give our customers new flexibility and create joint progress and success.

Many companies employ in-house manufacture of individual components used in their end products. Included in this category is a manufacturer who specializes in industrial lighting technology. With the complete outsourcing of the production of stamped and formed parts to STÜKEN Czech Republic, the company freed up in-house capacities and at the same time benefited from significant cost savings.

Challenge

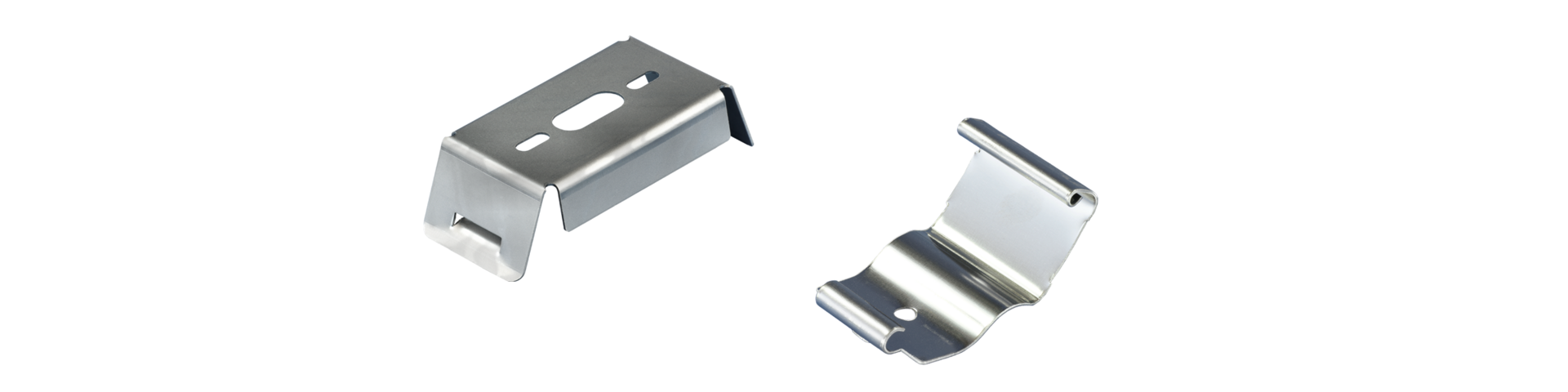

The customer wanted to develop a ceiling luminaire with a two-part body for industrial use in a wide variety of environments. The challenge for STÜKEN was to take over an existing component from the customer's own production and to achieve product and process optimization.

How can detachable and at the same time rust-free connecting elements between the upper and lower parts be produced much more efficiently?

Solution

After a joint discussion and comprehensive technical product analysis, stainless steel was determined to be the optimum material. Utilization of stainless steel also achieved the desired optical requirements for the component. The testing of all end products in which the new part was ultimately used led to successful protection certification for a wide range of applications. And because we are highly convinced of the improved quality of the product, the customer's LED luminaires are now also used extensively in the STÜKEN production plant in the Czech Republic.

STÜKEN MEANS MORE

Initial project related work began on the foundation of our customer's many years of experience in the field of lighting technology. This was complimented by our expertise in the design and manufacture of stamping tools and also our production of parts which must meet visual appearance standards. Our wide range of options for cleaning high-quality surfaces also played a decisive role. Just four months after the start of the project, we were already in series production and increased the customer's production volume threefold in a very short time.

Your Advantage

STÜKEN Czech Republic once again met all expectations and requirements by developing a precise, form-demanding stamped part with clearly defined mechanical properties and including a special surface finish. STÜKEN has been producing this component in large quantities and with guaranteed availability since 2010. Through continuing innovation, additional variants of the product have since been introduced into series production.

The advantages for our customers:

Flexibility, demand orientation and innovative solutions for your success

Thanks to our innovative strength, experience and flexibility in implementation, our customer was able to replace the established manufacturing process with our innovative solutions and possibilities. The capacities freed up by this optimization are used to advance the company's main technologies. A success for both sides.