西德克更胜一筹

凭借精密的模具,我们实施了人们认为不可行的解决方案。通过整合复杂的技术、后续加工工艺和服务,我们可以为客户创造增值的成果。

菜单

西德克更胜一筹

凭借精密的模具,我们实施了人们认为不可行的解决方案。通过整合复杂的技术、后续加工工艺和服务,我们可以为客户创造增值的成果。

联系我们

西德克精密拉深技术(上海)有限公司

中国上海浦东新区

临港万祥产业园万航路33号

邮编:201313

电话: +86 21 5804 1611

传真: +86 21 5804 2036

info@stueken.cn

其他联系方式

我们的生产和销售地点

Why the innovative production method offers you new perspectives and how you can even save costs in the process.

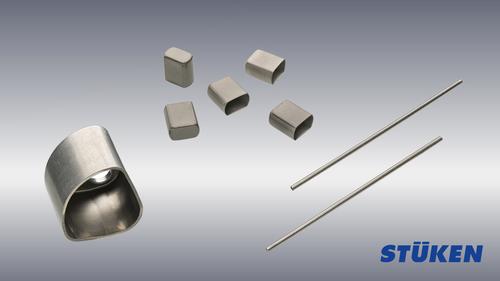

Rinteln, December 13th, 2022 - With its innovative process for deep drawing titanium, STÜKEN opens up new possibilities. High-precision titanium components with complex geometries can now be produced using the efficient, fast and resource-saving deep drawing technology. The customer benefits from remarkable cost savings.

Medical technology would be hard to imagine without titanium as a material. It has a high biocompatibility and is corrosion-resistant in contact with organic acids and chloride solutions. The material is also important in other industries, for example when low weight and temperature resistance are required. "Previously, precise components made of titanium could only be produced to a limited extent using deep-drawing technology," explains Nils Petersohn, Managing Director at STÜKEN. "Material forming over several stages was uneconomical due to the extreme stress on the tools." STÜKEN has developed an optimized process that allows titanium to be deep-drawn over a large number of stations. "This results in major cost advantages for pacemaker housings, for example, and also makes the use of deep-drawn titanium parts interesting for dental implant sleeves and similar applications."

The technology portfolio of the globally positioned company goes far beyond just deep-drawn parts. Supplemented with finishing processes that are precisely tailored to the customer's product, STÜKEN offers high-quality ready-to-use products that secure customers decisive competitive advantages. "For our customers in the medical technology sector, our Class 7 cleanrooms are of crucial importance. In conjunction with validated cleaning processes, we can ensure that there are no unwanted residues on the components and biocompatibility is guaranteed," says Petersohn. "We pull out all the stops to ensure that our customers are successful with their products."

Press contact

Hubert Stüken GmbH & Co. KG

Sandra Göhner-Baake, Marketing Manager

Phone: +49 5751 702 0

marketing@stueken.de