西德克更胜一筹

凭借精密的模具,我们实施了人们认为不可行的解决方案。通过整合复杂的技术、后续加工工艺和服务,我们可以为客户创造增值的成果。

菜单

西德克更胜一筹

凭借精密的模具,我们实施了人们认为不可行的解决方案。通过整合复杂的技术、后续加工工艺和服务,我们可以为客户创造增值的成果。

联系我们

西德克精密拉深技术(上海)有限公司

中国上海浦东新区

临港万祥产业园万航路33号

邮编:201313

电话: +86 21 5804 1611

传真: +86 21 5804 2036

info@stueken.cn

其他联系方式

我们的生产和销售地点

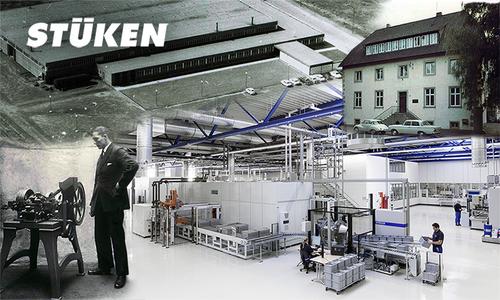

90 years of technological leadership and innovation

Rinteln, March 16th, 2021 – Deep drawing specialist STÜKEN celebrates its 90th anniversary. Hubert Stüken founded the family business in 1931. Today, the world market leader employs 1250 people at five locations in Europe, Asia and America.

Hubert Stüken started his own business in 1931. His first products were automatic machines for assembling buttons and wheels for toy cars. In 1958, the hundredth employee was hired and annual sales exceeded one million DM for the first time. In the 1970s, STÜKEN developed and built its first transfer presses in-house. This enabled rationalization, cost savings and volume growth. Further volume increases, growing cost pressure and the drive for competitive advantages led to the introduction of automatic stamping machines with progressive die technology in 1980. STÜKEN was able to achieve another major leap in productivity and passed on the benefits to its customers.

The 1990s were a decade of innovative products for STÜKEN in the automotive industry. Electronic braking systems, airbags, gasoline injection systems - the medium-sized company helped develop ways to make driving safer and more economical. With its innovative ability to replace complex turned parts with deep-drawn parts, STÜKEN set standards in terms of practicality and cost savings. Exports increased and internationalization began. The first foreign location, opened in the USA in 1998, was followed by a plant in the Czech Republic in 2005 and a production site in China in 2006. The product range was expanded to include stamped and formed parts, plastic injection molded components and assemblies.

With new machine types and technological innovations, STÜKEN repeatedly set new standards in the deep drawing industry. Dr. Hubert Schmidt, CEO at STÜKEN, cites deep drawing of stainless steels, eddy current testing technology, laser welding and the SWEP surface hardening process as examples. "Customers appreciate our competence for deep-drawn parts with particularly high degrees of forming, exceptional contours or extremely small dimensions. We offer a range of finishing processes that is unique in the industry. Our components are ready for use and can be processed directly. As a leading supplier of high-precision deep-drawn parts, we are a reliable partner for our customers - worldwide. They can count on our know-how. Our quality enjoys an excellent reputation." To ensure that this remains the case in the future, STÜKEN invests in research and development. "As a technology leader, we always want to be ahead of the game," says Dr. Schmidt. "Our ambition is to explore and expand the limits of what is possible. Courage, pioneering spirit and entrepreneurial vision have been firmly anchored in our corporate DNA since Hubert Stüken."

Press contact

Hubert Stüken GmbH & Co. KG

Sandra Göhner-Baake, Marketing Manager

Phone: +49 5751 702 0

marketing@stueken.de