STÜKEN MEANS MORE

With our precision parts, we implement solutions that even experts would not have considered feasible. We combine complex technologies, finishing processes and services and achieve results that add value for our customers.

Menu

STÜKEN MEANS MORE

With our precision parts, we implement solutions that even experts would not have considered feasible. We combine complex technologies, finishing processes and services and achieve results that add value for our customers.

Contact

Hubert Stüken GmbH & Co. KG

Alte Todenmanner Str. 42

31737 Rinteln

Germany

Phone +49 5751 702 0

info@stueken.de

Further Contacts

Here you will find our international production and sales locations.

Time-lapse video of the construction of our new logistics building

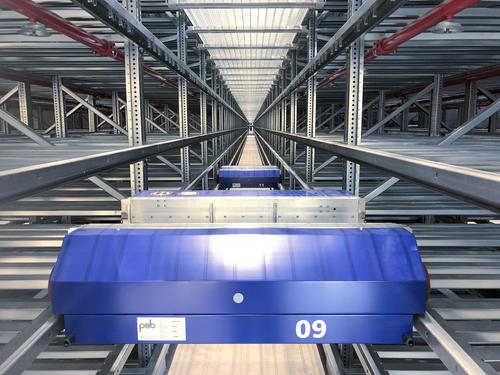

Creating quality in every business process with the state-of-the-art technology - that is STÜKEN. One of the largest investments in the company's history was the expansion, restructuring and modernization of the Rinteln-North site. The primary goal of this massive project was to secure the future viability of the company's German location. By improving the use of the production area, space for future growth was created. Automation, an improved material flow and even better technical cleanliness make the factory, which has grown over decades, fit for Industry 4.0 and the increasing demands of customers. A double-digit million Euro amount was invested in buildings, storage technology and transport systems.

This investment became visible primarily through the construction of the new logistics building. The ground-breaking ceremony took place in February 2018, and the interior work already began in November of the same year. In March 2019, work began on the logistics heart of the site: the automated storage system with 72,000 storage spaces. The rack system comprises three aisles and 15 levels. Six container lifts in the middle of the rack and three shuttle lifters at the beginning of the rack ensure that the 21 shuttles automatically bring the goods to the desired location. Automated guided vehicles are used in the building for the transport of washing baskets and semi-finished goods. Robots assist with palletizing, packing and filling crates.

We have captured the impressive construction phase from the ground-breaking ceremony to the completion of the storage system for you in a time-lapse video: