STÜKEN MEANS MORE

With our precision parts, we implement solutions that even experts would not have considered feasible. We combine complex technologies, finishing processes and services and achieve results that add value for our customers.

Menu

STÜKEN MEANS MORE

With our precision parts, we implement solutions that even experts would not have considered feasible. We combine complex technologies, finishing processes and services and achieve results that add value for our customers.

Contact

Hubert Stüken GmbH & Co. KG

Alte Todenmanner Str. 42

31737 Rinteln

Germany

Phone +49 5751 702 0

info@stueken.de

Further Contacts

Here you will find our international production and sales locations.

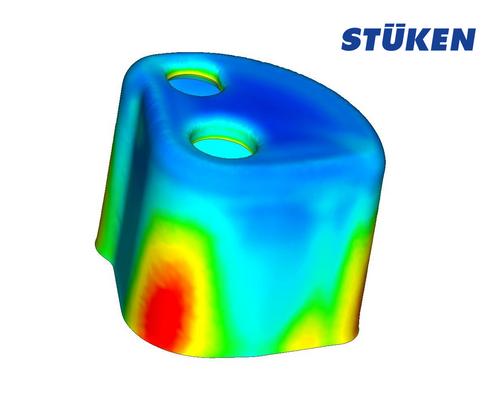

With FEA data, STÜKEN supports customers in product development

As part of the increasing digitalization, STÜKEN offers digital solutions in tool design and toolmaking. Customers benefit from a higher development speed and improved information gathering for decision-making.

Innovative companies aim to launch new products as quickly as possible - keyword "time to market". This requires an extremely fast development and manufacturing process. This in turn makes it necessary to obtain design feedback even before the first physical prototypes are created. This is where STÜKEN can support with a broad portfolio of digital solutions.

In the recent past, our customers' demand for deep drawing design support in the development phase has increased. 'Virtual try-outs' or testing in the early development phase have become more important. And we see an increasing need for functional validation. To meet these trends, STÜKEN supports its customers with data generated using Finite Element Analysis (FEA). With geometry data, we make virtual testing in the customer's CAD assembly possible. Forming data can provide the customer with information on which raw material is best suited for the component. During product development, STÜKEN supports its customers with FEA prototypes during design. The load on a component can also be simulated using FEA for different materials and designs. This provides customers with information on how to optimize their component design.

STÜKEN has developed a unique database of all parameters that are relevant for a simulation in terms of deep drawing. As a technology and innovation leader and thanks to decades of experience, we can offer data that is very close to reality. Our models are proven through countless customer projects and our own laboratory tests. The earlier we are involved in the product design phase, the better we can contribute to an efficient collaboration with the creativity and know-how of our experts. Together with our customers, we develop optimum components in terms of function, production and cost.