STÜKEN MEANS MORE

With our precision parts, we implement solutions that even experts would not have considered feasible. We combine complex technologies, finishing processes and services and achieve results that add value for our customers.

Menu

STÜKEN MEANS MORE

With our precision parts, we implement solutions that even experts would not have considered feasible. We combine complex technologies, finishing processes and services and achieve results that add value for our customers.

Contact

Hubert Stüken GmbH & Co. KG

Alte Todenmanner Str. 42

31737 Rinteln

Germany

Phone +49 5751 702 0

info@stueken.de

Further Contacts

Here you will find our international production and sales locations.

STÜKEN offers new process for the surface hardening of stainless steel components

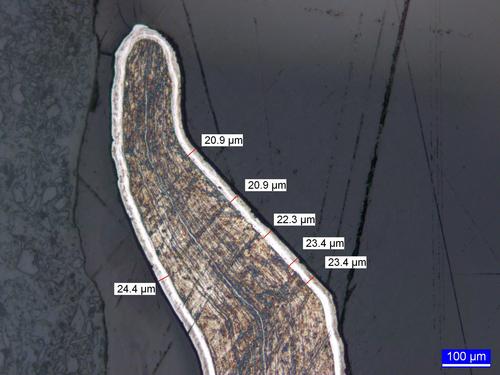

Rinteln, 21st March 2016 – STÜKEN, the global leader in manufacturing stamped and deep-drawn parts, now offers the SWEP15® process for the case hardening of stainless steel. With SWEP15®, surface hardness levels of more than 1,400 HV 0.1 can be achieved, the service life of components can be extended tenfold – and cost-efficient hardening as bulk material is possible.

Technical Managing Director Dr.-Ing. Uwe Krismann presents SWEP15® as the result of in-depth research and development work. "The result is a product that meets all conceivable requirements. Despite the hard surface, components maintain their strength and non-magnetic properties, the layer thickness is variable between 5 and 30 μm, and the sliding capacity is high." Furthermore, in thorough field tests, the diffusion layer has proved to be exceedingly resistant to chipping. For cost-conscious customers – and there are many of them – the fact that SWEP15® allows for hardening deep-drawn parts as bulk material is also highly interesting.

Dr.-Ing. Hubert Schmidt, Commercial Managing Director of STÜKEN, focuses on a further advantage: "Since we can offer everything from a single source, we have complete control over quality. This means security for our customers, and also creates organizational and logistic advantages which are soon reflected in financial terms."

SWEP15® was tried out in customer comparison tests, and is already used in numerous applications. For example, the process prevents seal seat wear in ABS valves.

As a result of improved fatigue strength under alternating stress, SWEP15® enables the lightweight design of components with up to 80% less wall thickness. This is accompanied by enormous savings potentials in material and weight.

Press contact

Hubert Stüken GmbH & Co. KG

Sandra Göhner, Marketing Manager

Phone: +49 5751 702 0

marketing@stueken.de